Introduction

This is part three of our four-part series comparing the top-used direct seeders on the market! In the previous article of this series, we provided an in-depth review of the Four-Row Pinpoint Seeder. The next step up in quality and performance is the Six-Row Seeder! Like the Four-Row, the Six-Row Seeder specializes in singulating medium to small seeds for densely sown crops like baby salad mixes and carrots.

However, instead of requiring three passes to create 12 evenly spaced rows on a 30” bed like the Four-Point, the Six-Row Seeder gets the job done in just two passes.

The Conception of the Six-Row Seeder

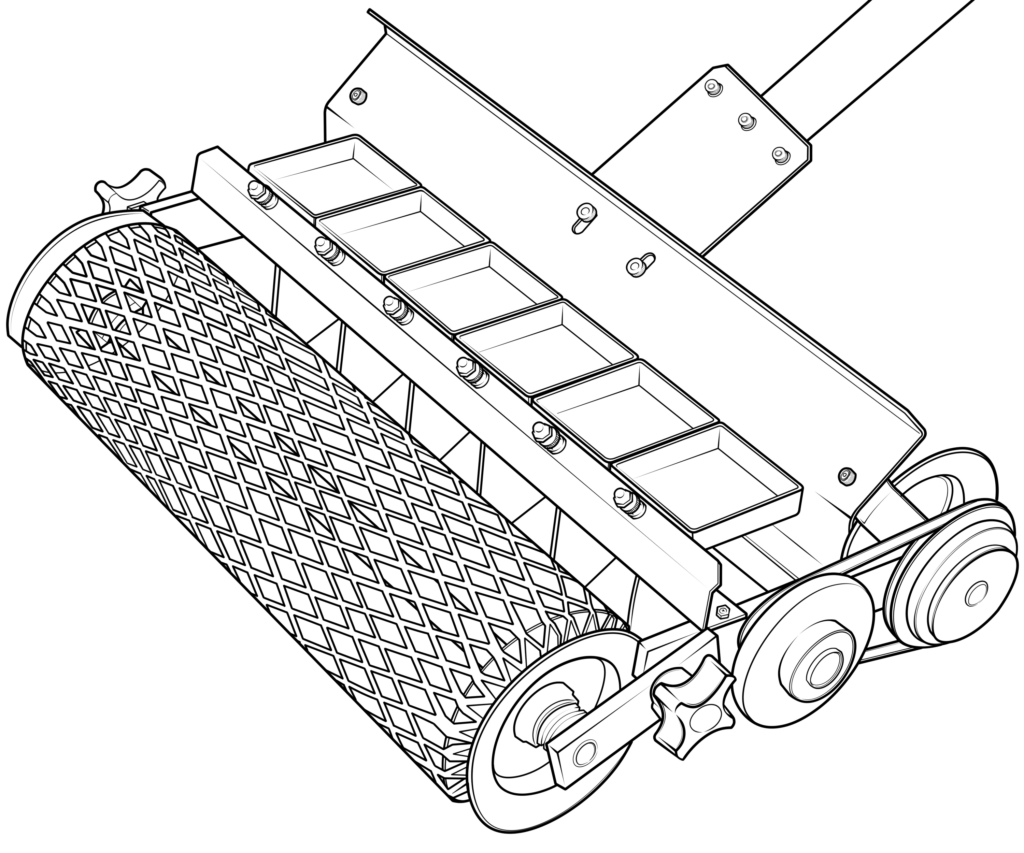

The Six-Row Seeder was developed in partnership with Eliot Coleman, a well-known pioneering organic farmer and author who has spent over 50 years researching and developing sustainable agriculture practices. Eliot Coleman was a big fan of the Four-Row Pinpoint Seeder and used it for many years. However, he wanted to improve it. He liked the 2¼-inch between-row spacing but wanted six rows instead of four. He had the idea to include small cage rollers, one in front and one behind the hoppers. The front cage roller would tamp the soil, while the rear roller would fill in the furrows and level the bed.

After working with engineers at Johnny’s Selected Seeds in Maine, his design became a reality. In addition to adding the two roller cages and six seed hoppers, they also engineered three different drive pulleys, with a drive belt to allow for three different in-row seed spacing options: 1”, 2”, or 4”.

Not only that, but they also included a seed depth adjustment into the front roller design, allowing it to be set with a screw knob. They also included a clear seed hopper lid, protecting seeds from water in the event of rain, or dripping condensation in greenhouses.

Upgrades From the Four-Row to the Six-Row Seeder

In review, these are the upgraded features that set apart Eliot Coleman’s Six-Row Seeder from the Four-Row Pinpoint Seeder:

- Six rows instead of four, allowing 12 rows to be seeded in just two passes on a 30” bed

- A roller cage on the front to tamp the soil, and a roller cage on the back to fill in the furrows and level the bed

- Three different drive pulleys, with a drive belt to allow for three different in-row seed spacing options: 1”, 2”, or 4”

- A clear acrylic seed hopper lid, protecting seeds from water in the event of rain, or dripping condensation in the greenhouse

How to Use the Six-Row Seeder

Bed Preparation

The careful bed preparation requirements for the Six-Row Seeder are the same as they are for the Four-Row. The soil must be a smooth consistency, typically requiring some kind of mechanized preparation by either a tiller, power harrow or a drill-powered tilther. It must be free from any rocks, previous crop residue, or any other debris. The soil should also be level, as any irregularities will cause uneven contact with the 15” wide cage rollers and six mini plows on the underside of the seeder.

The moisture level in the soil also plays an important role in the performance of the Six-Row Seeder. A dry and powdery soil can make it challenging to get enough traction for the cage rollers to rotate, which power the pulleys and cause the seed to drop consistently. Too much moisture can gum up in the plows and block the seed from dropping the way it’s supposed to.

For really dry soil, it’s recommended to lightly irrigate prior to operating the precision seeder. A pass with the 30″ Seed Roller (made by Johnny’s) to tamp the soil can also increase the traction and performance of the Six-Row Seeder. While it does have its own mini cage rollers, they don’t do quite the same job as the full-size 30” cage roller from Johnny’s, which also allows you to add weights for more efficient tamping and leveling of the soil.

Seed Sizes

The Six-Row Seeder offers four hole sizes on the seed shaft to accommodate medium to small seeds.

- Hole A

- Hole length: 3.5mm

- Hole Width: 3.5mm

- Hole Depth: 1mm

- Number of Holes on Shaft: 6

- Recommended Crops: Arugula, Claytonia

- Hole B

- Hole length: 6mm

- Hole Width: 5mm

- Hole Depth: 2mm

- Number of Holes on Shaft: 6

- Recommended Crops: Carrot (raw), Hakurei Salad Turnip, Lettuce, Mustard

- Hole C

- Hole length: 8mm

- Hole Width: 6mm

- Hole Depth: 3mm

- Number of Holes on Shaft: 6

- Recommended Crops: Brassicas, Bunching Onions, Tokyo Bakana

- Hole D

- Hole length: 10mm

- Hole Width: 8mm

- Hole Depth: 4mm

- Number of Holes on Shaft: 6

- Recommended Crops: Radish, Spinach

Johnny’s also makes an Extended Seed Shaft for the Six-Row Seeder. It offers two smaller hole sizes, and two larger hole sizes, allowing for an extended range of seeds that this seeder can accommodate.

Seeding

When preparing for seeding, slide the seed shaft into the seeder body to where the desired hole size for your seed is centered under each of the six hoppers. There is a set screw that can be tightened to hold the shaft in position, with machined notches for each hole size option. This is a nice feature that the Four-Row Pinpoint Seeder doesn’t have.

Next, fill each of the six seed hoppers with equal amounts of seed, and then install the lid.

Push the seeder slowly over your prepared bed, with the outer edge of the cage rollers following the outer edge of the bed. On the return pass, repeat the process for an evenly spaced 12 rows on a 30” bed.

Adjusting the Six-Row Seeder

Seeding Depth

There are two black knobs on either side of the frame that allows for adjusting the position of the front roller cage. Loosening the knobs allows you to rotate the arms on the side of the roller cage, to raise or lower it. Lowering the roller cage brings up the mini plows for shallower seeding, whereas raising the roller cage (to where the front and rear cage are at the same level) allows the seeder to sit flush with the soil level, putting the mini plows at their maximum depth.

Seed Brushes

Very similar to the Four-Row, the Six-Row Seeder has adjustable seed brushes designed to move away excess seed from the seed hole as it’s rotated and directed to the drop point. As with other seeders, raising the brush will accommodate larger or odd-sized seeds, or allow for more seeds to pass through if denser plantings are desired.

In-Row Spacing

Adjustable in-row spacing is another significant upgrade from the Four-Row to the Six-Row Seeder. Where the Four-Row was fixed at 1” in-row spacing, the Six-Row is equipped with a pulley system to offer a much wider range of options.

The pulley system has a small, medium, and large diameter pulley mounted on one end of the axle on the rear wheel/cage roller, and then another set of three pulleys mounted to the seed shaft on the front. They are connected with a simple black rubber drive band. Here are the different configurations to achieve the different in-row spacings:

- 4” In-Row Spacing

- Front: small diameter pulley

- Rear: large diameter pulley

- 2” In-Row Spacing

- Front: medium diameter pulley

- Rear: medium diameter pulley

- 1” In-Row Spacing

- Front: large diameter pulley

- Rear: small diameter pulley

Between-Row Spacing

The between-row spacing on the Six-Row Seeder is fixed at 2.5”. This is very similar to the Four-Row Seeder which is fixed at 2.25”. Like the Four-Row, you have the option to leave some hoppers empty to increase the space between rows. For example, filling just the first, third, and sixth hoppers would achieve 5” between row spacing.

Six-Row Seeder, Second Edition

Based on customer feedback and extensive field trials, Johnny’s Seeds recently developed a second edition Six-Row Seeder with some new and improved features! The 2.0 version includes the following upgrades:

- Powder-coated steel frame

- Tabs on the rear drive wheel for improved traction

- Open wheel ends for easily cleaning out the cages

- Seed funnel for collecting unused seed

- Adjustable offset handle

Powder-Coated Steel Frame

The powder-coated frame adds a nice aesthetic and adds an extra layer of protection from the elements for many years of use.

Tabs On Drive Wheel

Extra traction on the drive wheel (the rear cage roller) is definitely a nice addition. If the soil is on the loose side and you aren’t applying enough pressure on the drive wheel, it is often prone to not consistently spinning, which stalls the seed from dropping. The tabs or “teeth” that have been added should help solve that.

Open Wheel Ends

With the previous model having closed ends on the cage rollers, compost, and other soil debris would often get trapped inside, causing an annoying rattling while operating the seeder. Open ends allow the grower to pour out material that may get occasionally trapped in the roller cages.

Seed Funnel

A seed funnel for removing the excess seed from the hoppers after seeding is also another really nice addition. In the original model, one would have to turn the seeder on its side or upside down over a large enough container to catch the seed. This would often result in clumps of soil stuck to the seeder also falling out with the seed, requiring sifting.

Adjustable Offset Handle

The adjustable offset handle allows a grower to comfortably walk in a pathway beside the bed without leaning in or hyperextending their back while operating the Six-Row Seeder.

Conclusion

The Six-Row Seeder is essentially an upgraded/more evolved iteration of the Four-Row Pinpoint Seeder. The Four-Row retails for $279, while the Six-Row sells for $650. Do the upgraded features warrant over twice the price? If this is your farm’s go-to seeder for daily operations, then I would say they do.

With that said, it’s important to note that even with the added features, they still both require the same degree of extensive soil and bed preparation and the recommended additional step of tamping the bed with another large and awkward tool, the Seed Roller. They also both require optimal moisture levels in the soil for best performance.

What if there was a direct seeder that didn’t require this extensive bed preparation, and could operate smoothly even in soil that would ordinarily be deemed too dry, or too wet? What if…

Relevant Links

Jang JP_5 Seeder vs. Six-Row Seeder | The Four-Row Pinpoint Seeder | The Jang Seeder vs. The Earthway Seeder

Dalton Fashik

What is the average overall cost per unit of produce after all expenses and costs of doing business, unused pieces of paper pot, etc For the paper pot system.

(Not including the initial costs)

just ongoing regular purchasing.

This is what has kept me from considering the paper pot system. I just don’t know what my cost per unit would be and I don’t want to invest in a piece of equipment that could become a storage item if I’m not down with the reoccurring costs of the system.

I can buy transplants for .75/ea in bulk

For crops like lettuce which are a single harvest crop your system seems more efficient, but for crops that produce lots of fruits, a 1 time .75 cost plus hand sown investment seems more efficient.

I am really curious about the actual per unit costs on various common market garden crops.

Diego

For lettuce, the paper cost is $0.015 per plant. The cost savings come down to your labor rate. Once you get over $15 per hour (assuming you are around 20ppm) it is cheaper to Paperpot transplant than it is to pay someone to hand transplant.